what is Sheet Metal Fabrication working process?

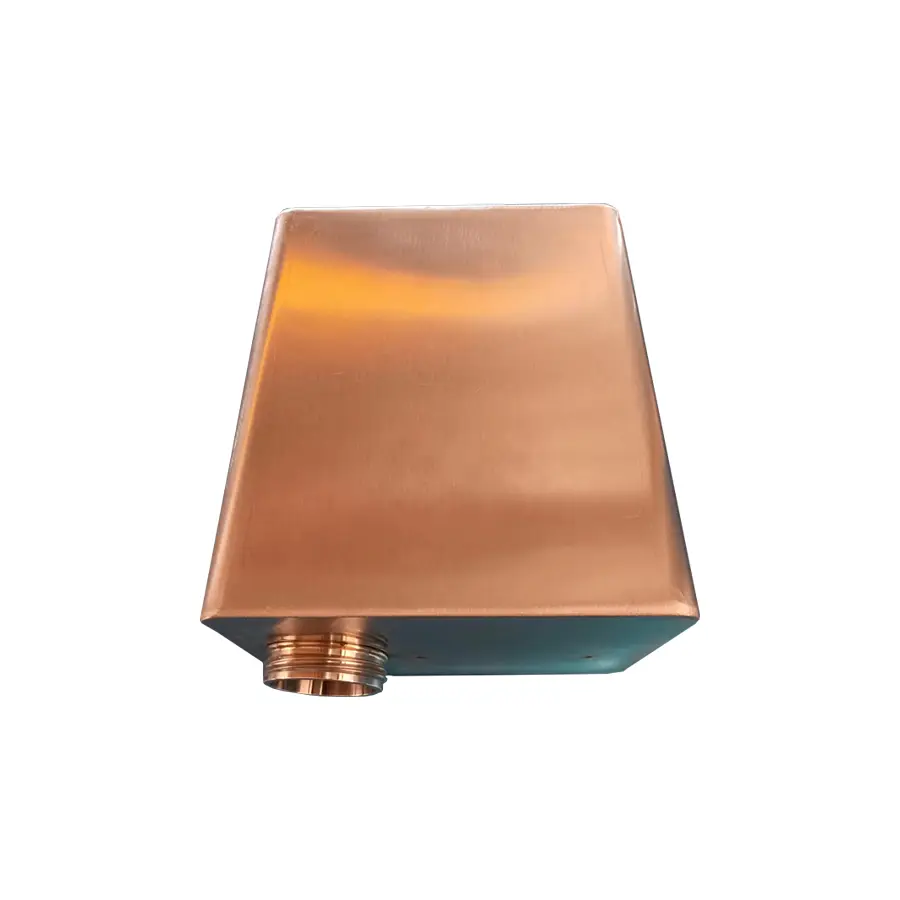

Metal fabrication is a process that involves cutting, shaping, and assembling metal to create a wide range of products. Sheet metal fabrication, in particular, is a specialized method that is used to create products and components for various industries. In this article, we will take a closer look at the sheet metal fabrication process, exploring its methods, applications, and benefits.

Understanding Sheet Metal Fabrication

Sheet metal fabrication is the process of forming metal sheets into the desired shape and size. This can be achieved through a variety of techniques, including cutting, bending, and assembling. The end result is a product or component that meets the specific requirements of the customer.

One of the key advantages of sheet metal fabrication is its versatility. It can be used to create a wide range of products, from simple brackets and enclosures to complex components for machinery and equipment. As a result, sheet metal fabrication is widely used in industries such as automotive, aerospace, electronics, and construction.

The sheet metal fabrication process varies depending on the specific requirements of the project. However, there are some common steps that are typically involved in the fabrication process. These include design and planning, material selection, cutting and shaping, assembly, and finishing. Each of these steps plays a crucial role in the overall process, ensuring that the final product meets the highest standards of quality and precision.

The Design and Planning Stage

The first step in the sheet metal fabrication process is the design and planning stage. This is where the customer's requirements are translated into a detailed design that will guide the fabrication process. During this stage, engineers and designers work closely with the customer to understand their needs and develop a design that meets those requirements.

In addition to the design, the planning stage also involves selecting the most suitable materials for the project. This is a critical step, as the choice of material will have a significant impact on the final product's performance and durability. Factors such as strength, flexibility, and corrosion resistance are carefully considered to ensure that the selected material meets the specific requirements of the project.

Once the design and material selection are finalized, the next step is to create a prototype or sample of the product. This allows the customer to review and approve the design before the fabrication process begins. It also provides an opportunity to make any necessary adjustments or refinements to the design before mass production.

Material Selection

When it comes to sheet metal fabrication, the selection of materials is crucial to the success of the project. Different metals offer varying properties, and these properties can have a significant impact on the final product's performance and longevity. Some of the most commonly used metals in sheet metal fabrication include steel, aluminum, and stainless steel.

Steel is a popular choice for sheet metal fabrication due to its strength, durability, and affordability. It can be easily formed and welded, making it suitable for a wide range of applications. Aluminum, on the other hand, is known for its lightweight and corrosion-resistant properties, making it ideal for products that require high strength-to-weight ratio and resistance to rust.

Stainless steel is another popular choice for sheet metal fabrication, thanks to its exceptional corrosion resistance and aesthetic appeal. It is often used in products that require high levels of hygiene and cleanliness, such as food processing equipment and medical devices. With the right material selection, sheet metal fabrication can produce products that are not only functional but also visually appealing.

Cutting and Shaping

Once the design is finalized and the materials are selected, the next step in the sheet metal fabrication process is cutting and shaping the metal sheets. This is typically done using a variety of techniques, such as shearing, punching, laser cutting, and plasma cutting. Each of these methods has its own advantages and limitations, and the choice of cutting technique will depend on the specific requirements of the project.

Shearing is a common method used to cut metal sheets into the desired shape and size. It involves placing the metal sheet between two blades and applying force to cut through the material. Shearing is suitable for straight cuts and is often used to cut large sheets of metal into smaller, more manageable pieces.

Punching is another popular cutting method that is used to create holes, notches, and other features in the metal sheet. This is achieved by using a punch and die set that applies high pressure to the metal, resulting in a clean and precise cut. Laser cutting, on the other hand, uses a high-powered laser to melt, burn, or vaporize the material, creating highly accurate and complex shapes with minimal heat-affected zones.

Plasma cutting is a versatile cutting technique that uses a high-velocity jet of ionized gas to melt and remove the metal. This method is ideal for cutting thicker materials and is often used for applications that require high precision and speed. Regardless of the cutting technique used, the goal is to achieve accurate and clean cuts that meet the design specifications of the product.

Assembly

Once the metal sheets are cut and shaped, the next step in the sheet metal fabrication process is assembly. This involves joining the individual components together to create the final product. Assembly techniques can vary depending on the complexity of the product and may include methods such as welding, riveting, and fastening.

Welding is a common assembly method used in sheet metal fabrication, especially for products that require strong and permanent bonds between metal components. It involves melting the edges of the metal parts and fusing them together to create a seamless and durable joint. Welding can be performed using various techniques, such as gas metal arc welding (MIG), gas tungsten arc welding (TIG), and spot welding.

Riveting is another popular assembly technique that is used to join metal components together using rivets. Rivets are mechanical fasteners that are inserted through pre-drilled holes and then deformed to create a strong, permanent joint. This method is ideal for applications that require high tensile strength and resistance to vibration and shear forces.

In addition to welding and riveting, sheet metal fabrication may also involve fastening techniques such as screws, bolts, and adhesives. These methods are suitable for products that require disassembly or reassembly, as they allow for easy access to the internal components. The choice of assembly technique will depend on factors such as product design, material properties, and manufacturing requirements.

Finishing

The final step in the sheet metal fabrication process is finishing, which involves applying surface treatments and coatings to the metal product. This not only enhances the product's aesthetic appeal but also provides protection against corrosion, wear, and other forms of damage. Some of the most commonly used finishing techniques in sheet metal fabrication include painting, powder coating, and plating.

Painting is a popular finishing method that is used to improve the appearance of the metal product while providing a protective barrier against environmental elements. It can be applied using spray guns, rollers, or brushes, and comes in a wide range of colors and textures to suit the customer's requirements. Powder coating is a similar method that uses electrostatically charged particles to create a durable and uniform finish on the metal surface.

Plating is another common finishing technique that involves applying a thin layer of metal, such as zinc or chrome, to the surface of the product. This not only enhances the product's appearance but also provides corrosion resistance and improved electrical conductivity. Other finishing techniques, such as anodizing and polishing, can also be used to achieve specific aesthetic and functional properties.

In conclusion, the sheet metal fabrication process is a versatile and essential method for creating a wide range of products and components. From the design and material selection to cutting, shaping, assembly, and finishing, each step plays a crucial role in ensuring that the final product meets the customer's exact requirements. By understanding the sheet metal fabrication process and its methods, applications, and benefits, manufacturers can produce high-quality products that are not only functional but also visually appealing.

Contact Person: Manager Zhang

Tel: +86-13817319695

WhatsApp:

+86-13817319695

+86-19821770068

Address:

No 18 Shihe Road, Touqiao Town, Fengxian District, Shanghai.