Sheet Metal Forming: How It Works, Processes, and Uses

Sheet Metal Forming: How It Works, Processes, and Uses

Introduction

Sheet metal forming is a widely used technique in manufacturing and engineering industries to shape and mold metal sheets into different forms and sizes. This process involves a variety of methods and techniques to achieve the desired results, making it an essential part of many production processes. In this article, we will explore how sheet metal forming works, the different processes involved, and the various uses of this versatile manufacturing method.

Understanding Sheet Metal Forming

Sheet metal forming is a manufacturing process that uses specialized equipment to shape and mold metal sheets into a variety of forms, including flat, curved, or complex shapes. This process is used to create a wide range of products, from simple household items to complex components for industries such as automotive, aerospace, and construction. The key to successful sheet metal forming lies in understanding the properties of the metal being worked with and the techniques required to shape it effectively.

One of the fundamental principles of sheet metal forming is to use the natural properties of the metal to create the desired shape. This often involves applying force or pressure to the metal sheet, causing it to deform and take on the desired form. There are various methods and techniques used in sheet metal forming, each tailored to suit different applications and requirements. Understanding these methods and techniques is essential for achieving high-quality results and ensuring the structural integrity of the formed components.

The Processes of Sheet Metal Forming

Sheet metal forming encompasses a wide range of processes, each with its own set of techniques and equipment. Some of the most common processes include bending, stretching, deep drawing, and roll forming. Bending is a process that involves deforming a metal sheet along a straight axis, typically using a press brake or similar equipment. Stretching, on the other hand, involves stretching the metal sheet to create a desired shape, often using hydraulic or mechanical presses.

Deep drawing is a process used to create deep, hollow shapes from metal sheets, such as cups or cylindrical containers. This process involves drawing the metal sheet into a die cavity, creating a seamless and uniform shape. Roll forming, on the other hand, involves passing a metal sheet through a series of rollers to gradually shape it into a desired profile. Each of these processes requires careful planning, precise equipment, and skilled operators to achieve the desired results.

Common Uses of Sheet Metal Forming

Sheet metal forming is used in a wide range of industries and applications, thanks to its versatility and ability to produce complex shapes and structures. In the automotive industry, sheet metal forming is used to create body panels, chassis components, and various structural elements. The aerospace industry relies on sheet metal forming to produce aircraft components, such as wings, fuselage sections, and engine parts. The construction industry also makes extensive use of sheet metal forming for applications such as roofing, cladding, and structural elements.

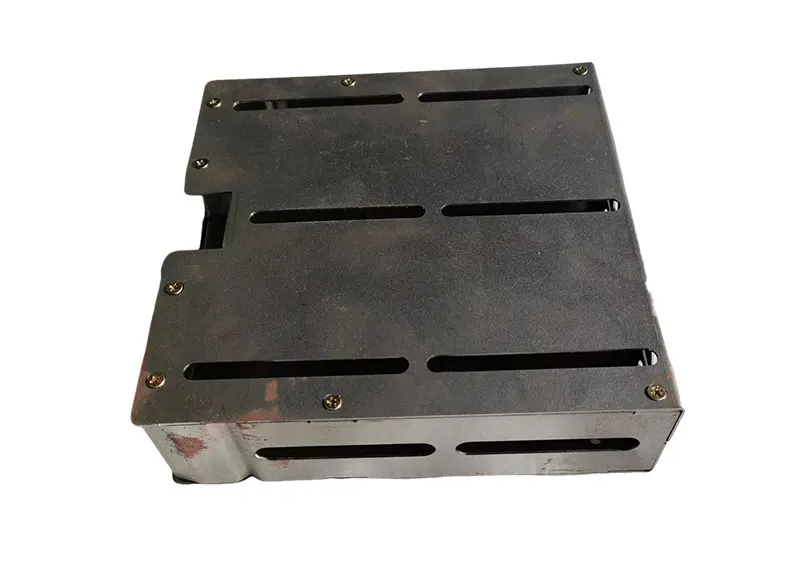

In addition to these large-scale applications, sheet metal forming is also used to produce a wide range of everyday items. From household appliances to electronic enclosures, sheet metal forming plays a crucial role in manufacturing products that are both functional and aesthetically pleasing. The ability to create complex shapes and structures from flat metal sheets makes this process indispensable in modern manufacturing and engineering.

Advancements in Sheet Metal Forming Technology

Advancements in technology have significantly improved the efficiency and precision of sheet metal forming processes. Computer-aided design (CAD) and computer-aided manufacturing (CAM) software have enabled engineers to simulate and optimize the forming process before physical production begins. This allows for more accurate designs, reduced material waste, and improved overall efficiency.

In addition to digital technology, advancements in material science have led to the development of new alloys and composites that offer superior formability and performance. These materials can be tailored to specific applications, allowing for greater design flexibility and enhanced product performance. Furthermore, the integration of automation and robotics has revolutionized the sheet metal forming industry, enabling faster production rates, higher precision, and improved safety for operators.

Conclusion

Sheet metal forming is a complex and versatile manufacturing process that plays a crucial role in the production of a wide range of products. Understanding the principles of sheet metal forming, the various processes involved, and the common uses of this technique is essential for anyone working in the manufacturing and engineering industries. With advancements in technology and materials, the future of sheet metal forming looks promising, with even greater potential for innovation and efficiency. Whether it's shaping automotive components, aerospace structures, or everyday items, sheet metal forming will continue to be a cornerstone of modern manufacturing.

Contact Person: Manager Zhang

Tel: +86-13817319695

WhatsApp:

+86-13817319695

+86-19821770068

Address:

No 18 Shihe Road, Touqiao Town, Fengxian District, Shanghai.