The Basics Knowledge of Sheet Metal Fabrication

Sheet metal fabrication is a process used to create objects out of thin metal sheets. It involves cutting, bending, and assembling the metal to create a final product. Many different industries use sheet metal fabrication, including automotive, aerospace, construction, and electronics. This article will explore the process of sheet metal fabrication, the tools and techniques used, and the applications of this versatile manufacturing method.

The Basics of Sheet Metal Fabrication

Sheet metal fabrication involves the manipulation of metal sheets to create a desired shape or product. The process typically starts with a flat metal sheet, which is then cut, bent, and assembled to form the final product. Sheet metal can be made from a variety of materials, including steel, aluminum, brass, copper, and titanium. Each material has its own unique properties, making it suitable for different applications.

One of the key aspects of sheet metal fabrication is the use of specialized tools and equipment. These can include shears for cutting the metal, press brakes for bending the metal, and welding machines for joining metal pieces together. Additionally, there are various techniques and processes used in sheet metal fabrication, such as punching, stamping, and rolling, each of which serves a specific purpose in creating the final product.

The Process of Sheet Metal Fabrication

The process of sheet metal fabrication can be broken down into several key steps. The first step is to design the product using computer-aided design (CAD) software. This allows the engineer to create a detailed 3D model of the product, including all the necessary dimensions and specifications. Once the design is complete, the next step is to create a pattern for the metal sheet. This can be done using a template, which is then used to trace the outline onto the metal sheet.

After the pattern has been created, the metal sheet is cut to size using shears or a CNC laser cutting machine. Precision is essential during this step to ensure the final product is accurate and meets the required specifications. Once the metal has been cut, it is then formed into the desired shape using a press brake or other bending equipment. This step requires careful precision to achieve the correct angles and bends in the metal.

Once the metal has been cut and formed, the next step is to assemble the various pieces together. This can be done using welding, riveting, or other fastening methods, depending on the specific requirements of the product. Finally, the finished product is inspected for quality and accuracy before being prepared for delivery to the customer.

Tools and Equipment Used in Sheet Metal Fabrication

Sheet metal fabrication requires a wide range of tools and equipment to complete the process. Some of the most commonly used tools include:

- Shears: Used to cut metal sheets to size. There are various types of shears, including manual, mechanical, and hydraulic shears, each suited to different types of metal and cutting requirements.

- Press Brakes: Utilized to bend metal sheets into the desired shape. Press brakes come in various sizes and configurations, and can be used for simple bends or complex forming operations.

- Welding Machines: Used to join metal pieces together through the process of melting and fusing. There are different types of welding machines, including MIG, TIG, and stick welders, each with its own applications and capabilities.

- CNC Laser Cutting Machines: These machines use a high-powered laser to cut precise patterns and shapes into metal sheets. They are capable of cutting through various materials, including steel, aluminum, and stainless steel.

- Punching and Stamping Equipment: Used to create holes, notches, or other features in metal sheets. These machines can be manual or automated, with the ability to produce high-precision results.

- Rolling Machines: Utilized for shaping metal sheets into curves, cylinders, or other forms. Rolling machines can be manual, mechanical, or CNC-controlled, and are essential for creating complex shapes in sheet metal fabrication.

Applications of Sheet Metal Fabrication

Sheet metal fabrication has a wide range of applications across various industries. Some common examples include:

- Automotive Industry: Sheet metal fabrication is used to create car body panels, chassis components, and exhaust systems. It is also used in the production of aircraft, trains, and other vehicles.

- Construction Industry: Sheet metal fabrication is utilized in the construction of buildings, bridges, and other structures. It is used for roofing, cladding, and architectural features, as well as for HVAC systems and ductwork.

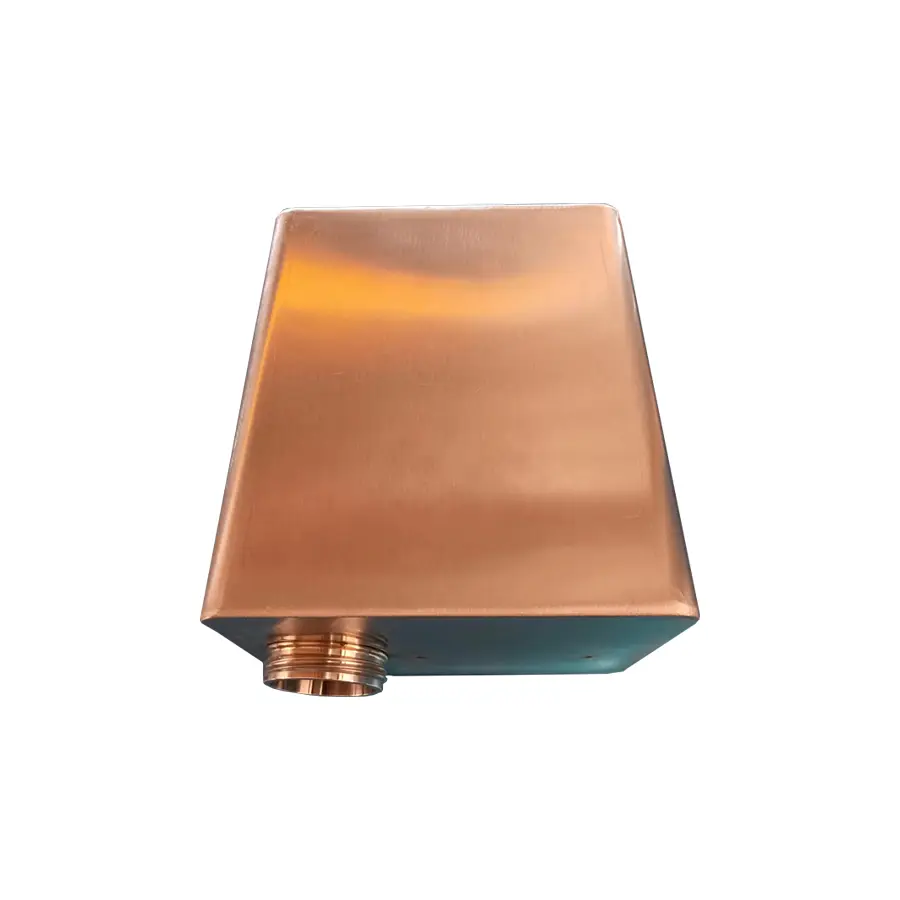

- Electronics Industry: Sheet metal fabrication is used to create enclosures, cabinets, and other components for electronic devices. It is also used in the production of server racks, control panels, and other equipment.

- Aerospace Industry: Sheet metal fabrication is essential for the production of aircraft components, including wings, fuselage sections, and engine parts. It is also used in the manufacture of spacecraft and satellite components.

- Manufacturing Industry: Sheet metal fabrication is used to produce a wide range of products, including machinery parts, tools, and consumer goods. It is also employed in the production of food processing equipment, agricultural machinery, and industrial components.

Conclusion

Sheet metal fabrication is a versatile and essential manufacturing process that is used in a wide range of industries. It involves the manipulation of metal sheets using specialized tools and techniques to create a variety of products, from car parts to electronic enclosures. With its many applications and capabilities, sheet metal fabrication plays a crucial role in modern manufacturing and will continue to be an integral part of the industrial landscape. Whether it's creating custom prototypes or mass-producing parts, sheet metal fabrication offers a cost-effective and efficient solution for producing high-quality metal products.

Contact Person: Manager Zhang

Tel: +86-13817319695

WhatsApp:

+86-13817319695

+86-19821770068

Address:

No 18 Shihe Road, Touqiao Town, Fengxian District, Shanghai.