Sheet Metal Fabrication: A Comprehensive Guide

Sheet Metal Fabrication: A Comprehensive Guide

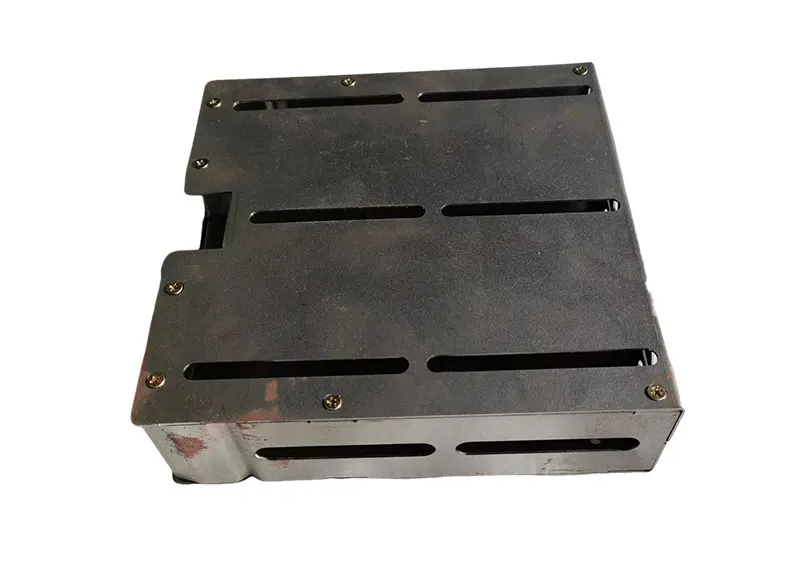

Sheet metal fabrication is a widely used metalworking process that involves cutting, bending, and assembling metal to create a variety of products. From car parts to household appliances, sheet metal fabrication plays a critical role in the manufacturing industry. In this comprehensive guide, we will explore the ins and outs of sheet metal fabrication, including its various processes, applications, and the tools and equipment involved.

The Basics of Sheet Metal Fabrication

Sheet metal fabrication involves transforming flat sheets of metal into specific shapes and structures. The process typically begins with the cutting of the metal sheet into the desired size and shape using specialized tools such as shears, lasers, or water jets. Once the metal is cut, it undergoes various forming processes, such as bending and stretching, to achieve the desired shape. Finally, the formed metal pieces are assembled using welding, riveting, or other joining methods. It is a versatile and cost-effective method of producing complex parts and components.

The Processes Involved in Sheet Metal Fabrication

There are several processes involved in sheet metal fabrication, each serving a unique purpose in shaping and assembling the metal. One of the most common processes is cutting, which can be accomplished through various methods such as shearing, punching, or laser cutting. Another critical process is bending, which involves deforming the metal sheet to create angles, curves, and other geometric shapes. Other processes include forming, welding, and finishing, all of which contribute to the final product's functionality and appearance.

The Tools and Equipment Used in Sheet Metal Fabrication

Sheet metal fabrication requires a range of specialized tools and equipment to carry out the various processes involved. Cutting processes utilize tools such as shears, plasma cutters, and water jets, each with its own unique capabilities and advantages. Bending and forming processes rely on equipment like press brakes and rollers, which can accurately shape the metal to the desired specifications. Welding and joining processes require equipment such as MIG and TIG welders, as well as riveting and fastening tools to securely assemble the metal components. Additionally, finishing processes may involve grinding, deburring, and coating equipment to achieve the desired surface finish.

Applications of Sheet Metal Fabrication

Sheet metal fabrication is used in a wide range of industries and applications, from automotive and aerospace to construction and electronics. In the automotive industry, sheet metal fabrication is essential for producing car body panels, chassis components, and exhaust systems. In the aerospace industry, it is used to manufacture aircraft structures, engine components, and interior fittings. In the construction industry, sheet metal fabrication is employed to create HVAC systems, roofing, and structural components. Additionally, sheet metal fabrication is used to produce a variety of consumer goods, such as household appliances, furniture, and decorative items.

Challenges and Considerations in Sheet Metal Fabrication

While sheet metal fabrication offers numerous benefits, such as versatility and cost-effectiveness, there are also challenges and considerations to be aware of. One of the primary challenges is material selection, as different types of metals have varying mechanical properties and workability. Additionally, achieving precise tolerances and maintaining structural integrity can be challenging, particularly for complex part geometries. It is essential to consider factors such as material thickness, bend radii, and tooling requirements to ensure the successful fabrication of the desired components.

In conclusion, sheet metal fabrication is a versatile and essential process in the manufacturing industry, with a wide range of applications and processes. By understanding the basics of sheet metal fabrication, the various processes and equipment involved, and the challenges and considerations, manufacturers can effectively utilize this method to produce high-quality metal components and products. Whether it's creating automotive parts, aerospace components, or consumer goods, sheet metal fabrication continues to play a crucial role in shaping the modern world.

Contact Person: Manager Zhang

Tel: +86-13817319695

WhatsApp:

+86-13817319695

+86-19821770068

Address:

No 18 Shihe Road, Touqiao Town, Fengxian District, Shanghai.