How to make custom sheet metal bracket styles

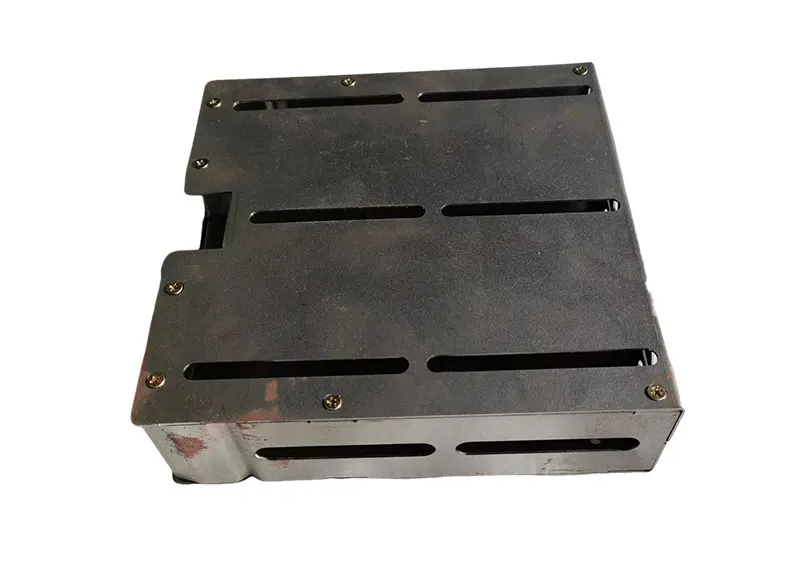

Sheet metal brackets are crucial components in various industries, from automotive to construction. They provide structural support and stability for a wide range of applications. While standard sheet metal brackets are readily available, custom sheet metal brackets offer a more tailored solution for specific needs. In this article, we will discuss how to make custom sheet metal bracket styles, providing detailed instructions and tips for creating brackets that meet your unique requirements.

Understanding Custom Sheet Metal Brackets

Custom sheet metal brackets are designed to address specific needs and requirements that cannot be met by off-the-shelf brackets. This may include unique dimensions, specific load-bearing capacity, or special mounting requirements. By customizing the design of sheet metal brackets, you can ensure that they fit seamlessly into your project and provide the necessary support and functionality.

When creating custom sheet metal brackets, it is important to take into account the material, thickness, and overall design of the bracket. The choice of material will depend on the application and the environment in which the bracket will be used. For example, stainless steel is often used for brackets in corrosive environments, while aluminum is preferred for its lightweight properties. The thickness of the sheet metal will be determined by the load that the bracket needs to support, with thicker gauges used for heavier loads. The overall design of the bracket, including its shape and mounting options, will be tailored to the specific requirements of the project.

Design Considerations for Custom Sheet Metal Brackets

When designing custom sheet metal brackets, several key considerations should be taken into account to ensure that the brackets meet the desired specifications. These considerations include the load requirements, material selection, fabrication processes, and any additional features that may be necessary for the specific application.

Load Requirements: The first step in designing custom sheet metal brackets is to determine the load requirements. This includes calculating the maximum load the brackets will need to support, as well as any dynamic or static loads that may be present. Understanding the load requirements will help in selecting the appropriate material and thickness for the brackets, as well as the overall design.

Material Selection: The choice of material for custom sheet metal brackets is critical to their performance and longevity. Factors to consider when selecting the material include the environmental conditions in which the brackets will be used, the required strength and durability, and any special properties that may be needed, such as corrosion resistance or electrical conductivity.

Fabrication Processes: The fabrication processes used to create custom sheet metal brackets will depend on the design and material chosen. Common fabrication processes for sheet metal brackets include laser cutting, bending, welding, and finishing. Understanding the capabilities of these processes and their implications for the design will ensure that the brackets can be manufactured to the desired specifications.

Additional Features: Depending on the application, custom sheet metal brackets may require additional features such as holes for mounting, slots for adjustability, or reinforcements for increased strength. These additional features should be incorporated into the design to ensure that the brackets fulfill their intended purpose.

Creating Custom Sheet Metal Brackets

Once the design considerations have been addressed, the process of creating custom sheet metal brackets can begin. This typically involves several key steps, including material selection, design prototyping, fabrication, and finishing. Each step in the process is critical to the final quality and performance of the brackets.

Material Selection: As mentioned earlier, the choice of material for custom sheet metal brackets is a crucial decision that will impact their performance and durability. Factors to consider when selecting the material include the load requirements, environmental conditions, and any special properties that may be necessary. Once the material has been chosen, the appropriate sheet metal can be sourced for fabrication.

Design Prototyping: Before proceeding with the fabrication of custom sheet metal brackets, it is advisable to create prototypes to test the design and ensure that it meets the desired specifications. This may involve using computer-aided design (CAD) software to create a virtual model of the brackets, which can then be used to produce physical prototypes through 3D printing or other rapid prototyping methods.

Fabrication: The fabrication of custom sheet metal brackets will involve the use of various manufacturing processes to shape the raw material into the desired form. Common fabrication processes include cutting, bending, welding, and finishing. These processes require specialized equipment and skilled operators to ensure that the brackets are manufactured to the required specifications.

Finishing: Once the custom sheet metal brackets have been fabricated, they may require finishing processes to enhance their appearance or properties. This can include painting, powder coating, or other surface treatments to provide corrosion resistance or improve aesthetics. The finishing processes should be selected based on the material and environmental conditions in which the brackets will be used.

Applications of Custom Sheet Metal Brackets

Custom sheet metal brackets have a wide range of applications across various industries. They are used to provide structural support and stability in numerous settings, from industrial machinery to architectural components. Some common applications of custom sheet metal brackets include:

Industrial Machinery: Custom sheet metal brackets are used in industrial machinery to support and secure components such as motors, pumps, and conveyor systems. They are designed to withstand heavy loads and harsh operating conditions, providing the necessary structural integrity for reliable performance.

Construction and Architecture: In the construction and architecture industries, custom sheet metal brackets are used to support structural elements such as beams, columns, and trusses. They can be tailored to fit specific building designs and load requirements, providing essential support for various building components.

Automotive and Transportation: Custom sheet metal brackets are essential components in the automotive and transportation industries, where they are used to secure components such as exhaust systems, suspension components, and body panels. The brackets must meet stringent requirements for strength, durability, and weight, making customization essential.

Electrical and Electronics: Custom sheet metal brackets are utilized in the electrical and electronics industries to support and secure components such as circuit boards, power supplies, and enclosures. They are tailored to fit the specific dimensions and mounting requirements of electronic devices, ensuring proper functionality and safety.

Medical and Laboratory: In the medical and laboratory fields, custom sheet metal brackets are used to support equipment such as diagnostic instruments, laboratory apparatus, and medical devices. These brackets are designed to meet strict requirements for cleanliness, stability, and compatibility with sensitive equipment.

Conclusion

Custom sheet metal brackets offer a tailored solution for specific needs and requirements across various industries. By understanding the design considerations, fabrication processes, and applications of custom sheet metal brackets, individuals and businesses can create brackets that meet their unique specifications and provide the necessary support and stability. Whether used in industrial machinery, construction, automotive, electronics, or medical settings, custom sheet metal brackets play a crucial role in ensuring the functionality and reliability of various systems and components.

In summary, the process of creating custom sheet metal brackets involves careful consideration of load requirements, material selection, design prototyping, fabrication processes, and finishing. Each step in the process is critical to the final quality and performance of the brackets. By following these guidelines and understanding the applications of custom sheet metal brackets, individuals and businesses can achieve the desired results and meet their specific needs for structural support and stability.

Contact Person: Manager Zhang

Tel: +86-13817319695

WhatsApp:

+86-13817319695

+86-19821770068

Address:

No 18 Shihe Road, Touqiao Town, Fengxian District, Shanghai.