How does a bus bar work?

How Does a Bus Bar Work?

If you've ever taken a close look at the electrical system of a building or a piece of heavy machinery, you may have noticed a long, rigid piece of metal running alongside the electrical components. This inconspicuous yet essential component is called a bus bar. Despite its unassuming appearance, a bus bar plays a crucial role in electrical systems of all sizes, from small residential buildings to large commercial facilities. But how does a bus bar work, exactly? In this article, we'll explore the ins and outs of bus bars, including their function, types, and applications.

Understanding the Basics of Bus Bars

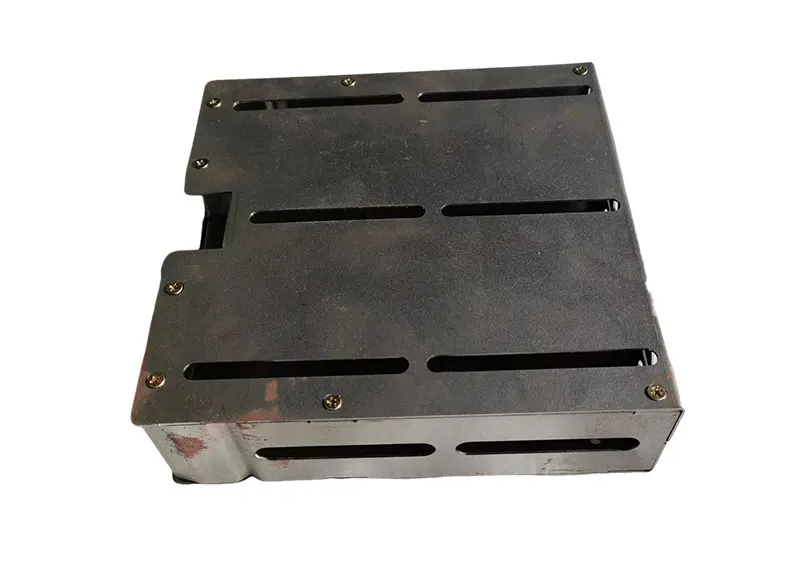

To comprehend how a bus bar works, it's essential to first understand what it is and its basic function in an electrical system. At its core, a bus bar is a metallic strip or bar used to conduct electricity within a power distribution system. It serves as a common connection point for multiple electrical circuits, allowing for the efficient and organized distribution of power throughout a facility. This common connection helps streamline the electrical system and reduce the amount of wiring needed, leading to cost savings and improved safety.

Bus bars are typically made from highly conductive metals such as copper or aluminum, as these materials offer low resistance to the flow of electricity. The bus bar is usually mounted within an electrical panel or switchgear and is connected to the main power source. From there, smaller branch circuits can be connected to the bus bar, allowing for the distribution of power to various electrical loads. In essence, the bus bar acts as a central hub for distributing electrical power, making it a critical component in any electrical system.

In addition to their role in power distribution, bus bars also play a crucial role in grounding and bonding within an electrical system. Grounding bus bars provide a common connection point for the grounding conductors of electrical circuits, helping to prevent electrical shock and safeguard against electrical fires. Bonding bus bars, on the other hand, are used to establish a reliable electrical connection between various metal components within a system, ensuring the safe dissipation of electrical currents and preventing the buildup of static electricity.

The Different Types of Bus Bars

While the basic function of a bus bar remains the same across different applications, there are several variations in terms of design, material, and purpose. Understanding these different types of bus bars is essential for selecting the right option for a specific electrical system.

One common distinction is the shape of the bus bar. Flat bus bars are the most straightforward design, consisting of a simple, flat strip of metal. These are commonly used in electrical panels and switchgear due to their compact size and ease of installation. In contrast, tubular bus bars are cylindrical in shape and are often used in high-voltage applications, where their larger surface area helps to dissipate heat more effectively.

Another important consideration is the material used for the bus bar. As mentioned earlier, copper and aluminum are the most commonly used materials due to their excellent conductivity. Copper bus bars are favored for their superior electrical and thermal conductivity, making them ideal for applications requiring high power transmission. Aluminum bus bars, on the other hand, are lightweight and cost-effective, making them a popular choice for large-scale power distribution systems.

In addition to these basic distinctions, bus bars can also be categorized based on their specific functions within an electrical system. For example, power bus bars are dedicated to transmitting electrical power, while ground bus bars are designed specifically for grounding purposes. Other specialized variations include neutral bus bars, which provide a common connection point for neutral conductors, and distribution bus bars, which are used to distribute power to various branch circuits.

Applications of Bus Bars

The versatility and efficiency of bus bars make them a fundamental component in a wide range of electrical applications. One of the most common uses of bus bars is in electrical panels and switchgear, where they serve as the central hub for power distribution. By connecting the main power source to the branch circuits, bus bars help ensure a consistent and organized flow of electricity throughout the system.

Bus bars are also widely used in industrial settings, particularly in manufacturing facilities and power plants. In these environments, bus bars play a critical role in transmitting large amounts of electrical power to various machinery and equipment. Their high conductivity and ability to dissipate heat make them well-suited for the rigorous demands of industrial applications.

In addition to their role in power distribution, bus bars are also essential in renewable energy systems, such as solar and wind power installations. These systems rely on bus bars to efficiently transmit power generated by solar panels or wind turbines to the grid or storage systems. Bus bars help minimize energy loss and ensure a reliable flow of renewable energy to meet the demands of residential and commercial consumers.

Beyond these primary applications, bus bars can be found in numerous other settings, including data centers, telecommunications infrastructure, and transportation systems. Their ability to streamline power distribution and support grounding and bonding requirements makes them a versatile solution for a wide range of electrical needs.

Installing and Maintaining Bus Bars

Proper installation and maintenance of bus bars are essential for ensuring the safety and reliability of an electrical system. During the installation process, careful attention must be paid to the selection of bus bar materials, sizing, and connections to ensure optimal performance. It's crucial to follow industry standards and manufacturer guidelines to prevent issues such as overheating, electrical arcing, or poor conductivity.

Regular maintenance is also critical to keep bus bars in good working condition. This includes inspecting for signs of corrosion, loose connections, or physical damage that could compromise the integrity of the bus bar. Proper cleaning and tightening of connections, as well as thermal inspections, can help identify potential issues before they escalate into more significant problems.

In some cases, it may be necessary to upgrade or expand bus bar systems to accommodate changes in electrical load or system requirements. This could involve adding additional bus bars, upgrading to larger capacity bus bars, or implementing new configurations to improve power distribution efficiency. Consulting with a qualified electrical professional is essential when making such modifications to ensure compliance with regulations and standards.

The Future of Bus Bars

As the demand for efficient and sustainable energy solutions continues to grow, the role of bus bars in electrical systems is likely to become even more prominent. Advances in materials and manufacturing technologies are driving innovation in bus bar design, with an emphasis on improving conductivity, heat dissipation, and reliability. Additionally, the integration of smart grid technologies and renewable energy sources is raising new challenges and opportunities for bus bar applications.

In the coming years, we can expect to see bus bars playing a key role in shaping the future of electrical infrastructure, from enhancing the efficiency of power transmission to supporting the expansion of renewable energy systems. As new technologies and solutions emerge, bus bars will remain a cornerstone of modern electrical systems, providing essential support for the transmission, distribution, and grounding of electrical power.

In conclusion, bus bars are a fundamental component of electrical systems, providing a reliable and efficient means of distributing power while ensuring safety and compliance with electrical standards. Their versatility and adaptability make them essential in a wide range of applications, from residential and commercial buildings to industrial facilities and renewable energy installations. By understanding the function, types, applications, and maintenance of bus bars, electrical professionals can ensure the continued reliability and performance of electrical systems for years to come.

Contact Person: Manager Zhang

Tel: +86-13817319695

WhatsApp:

+86-13817319695

+86-19821770068

Address:

No 18 Shihe Road, Touqiao Town, Fengxian District, Shanghai.