Basics of the Sheet Metal Fabrication Process

The sheet metal fabrication process is an essential part of many industries, including automotive, aerospace, construction, and more. It involves the manipulation of sheet metal to create various products and components. This process requires skilled professionals, advanced machinery, and an in-depth understanding of the properties of different metals. In this article, we will explore the sheet metal fabrication process in detail, including the various techniques and applications.

Understanding Sheet Metal Fabrication

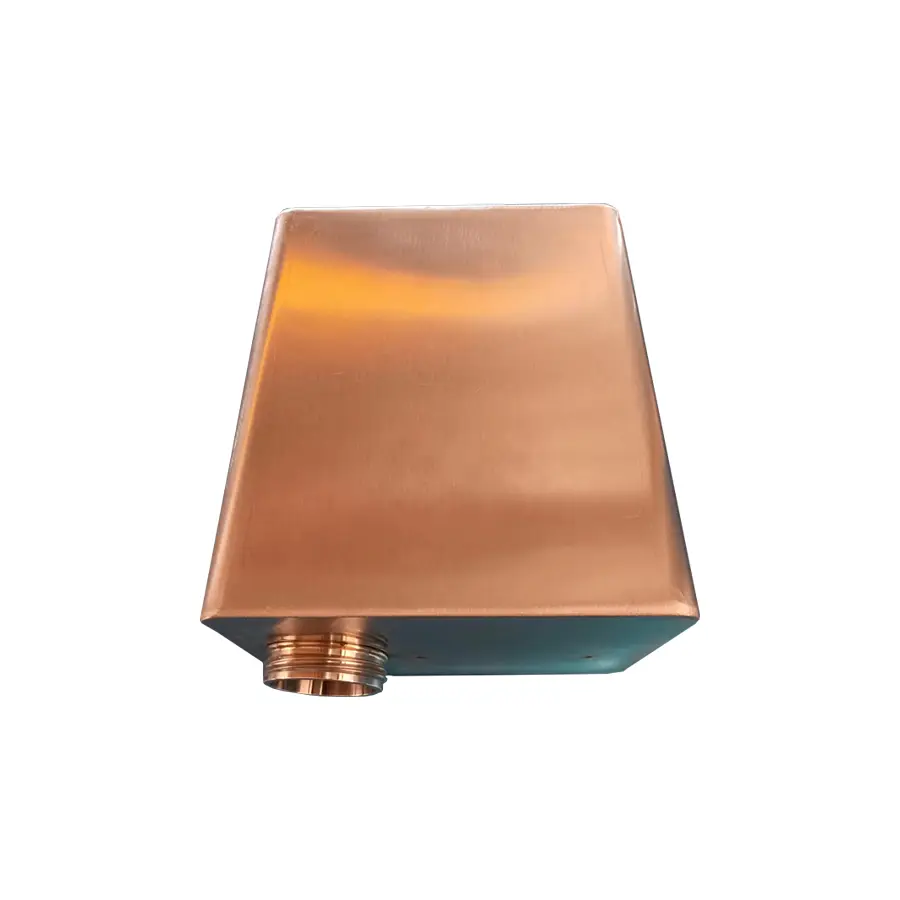

Sheet metal fabrication is the process of forming flat sheets of metal into a desired shape, size, and thickness. The process involves cutting, bending, shaping, and assembling the metal to create a wide range of products, such as car parts, aircraft components, household appliances, and more. Sheet metal, which is typically made of steel, aluminum, brass, copper, or nickel, is a versatile material that can be easily manipulated to meet specific design requirements.

The first step in the sheet metal fabrication process is the cutting of the metal sheets to the required dimensions. This can be done using various methods, such as shearing, sawing, or punching. Once the metal sheets are cut, they are then shaped and formed using techniques such as bending, rolling, and stretching. Bending is often done using a press brake, which applies force to the metal to bend it at a specific angle. Rolling involves passing the metal through a series of rollers to create cylindrical or curved shapes. Stretching is used to increase the surface area of the metal without changing its thickness.

Types of Sheet Metal Fabrication Techniques

There are several techniques used in the sheet metal fabrication process, each with its own unique advantages and applications. One of the most common techniques is welding, which is used to join separate metal pieces together. Welding can be done using various methods, such as MIG (metal inert gas) welding, TIG (tungsten inert gas) welding, and spot welding. Each method has its own advantages and is suitable for different types of metal and applications.

Another important technique in sheet metal fabrication is stamping, which involves using a press to create complex shapes and designs on the metal surface. Stamping is commonly used in the automotive and aerospace industries to produce parts with high precision and consistency. Other techniques such as laser cutting, plasma cutting, and waterjet cutting are also used to cut and shape metal with high accuracy and minimal material waste.

Applications of Sheet Metal Fabrication

The sheet metal fabrication process has a wide range of applications across various industries. In the automotive industry, sheet metal is used to manufacture car bodies, chassis, exhaust systems, and other components. The aerospace industry relies on sheet metal fabrication to produce aircraft parts, such as wings, fuselage, and engine components. In the construction industry, sheet metal is used for roofing, cladding, ventilation systems, and structural components.

Sheet metal fabrication is also essential in the manufacturing of household appliances, such as refrigerators, ovens, and washing machines. The precision and durability of sheet metal products make them ideal for use in consumer electronics, telecommunications, and medical devices. Additionally, sheet metal fabrication plays a crucial role in the energy sector, where it is used to produce components for solar panels, wind turbines, and electrical enclosures.

Advancements in Sheet Metal Fabrication

Advancements in technology have significantly impacted the sheet metal fabrication process, leading to improved efficiency, precision, and productivity. The introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) software has revolutionized the way sheet metal products are designed and produced. These software tools allow engineers to create detailed 3D models of metal parts, which can then be directly translated into machine instructions for cutting, bending, and welding.

Furthermore, the development of advanced machinery, such as CNC (computer numerical control) machines, laser cutters, and robotic automation systems, has made the sheet metal fabrication process faster and more reliable. CNC machines can perform complex cutting and shaping operations with high accuracy, while robotic systems can handle repetitive tasks with precision and consistency. These advancements have not only improved the quality of sheet metal products but have also reduced manufacturing lead times and costs.

Challenges in Sheet Metal Fabrication

Despite the numerous advancements in sheet metal fabrication, there are still challenges that manufacturers face in the process. One of the primary challenges is the selection of the right material for a specific application. Different metals have unique properties, such as strength, ductility, conductivity, and corrosion resistance, which must be carefully considered when choosing the appropriate material for a project. Additionally, the complexity of certain designs and the tight tolerances required for precision parts can pose challenges in the fabrication process.

Another challenge in sheet metal fabrication is the need for skilled labor and expertise. Operating advanced machinery and performing complex fabrication techniques require trained professionals who understand the intricacies of metalworking. Furthermore, the constantly changing market demands and customer requirements necessitate flexibility and adaptability in the fabrication process, which can be challenging for some manufacturers.

In summary, sheet metal fabrication is a complex and essential process that involves the manipulation of metal sheets to create a wide range of products. Various techniques, such as cutting, bending, welding, and stamping, are used to shape and assemble sheet metal into functional components for industries such as automotive, aerospace, construction, and more. Advancements in technology have led to improved efficiency and precision in the fabrication process, but challenges such as material selection and skilled labor continue to impact the industry. Despite these challenges, sheet metal fabrication remains a crucial part of modern manufacturing, driving innovation and progress in various sectors.

Contact Person: Manager Zhang

Tel: +86-13817319695

WhatsApp:

+86-13817319695

+86-19821770068

Address:

No 18 Shihe Road, Touqiao Town, Fengxian District, Shanghai.